Understanding Oilfield Supply Chain Risks and Mitigation Strategies

Geopolitical Risk

One of the most significant risks that oilfield supply centres face is supply chain disruptions caused by geopolitical events. For example, political instability or sanctions in a country where we source our equipment can cause delays or even stoppage of the supply of goods. To mitigate this risk, we maintain a diversified supplier base so that we are not reliant on a single source of supply. This enables us to quickly switch suppliers when one is affected by geopolitical events, ensuring that we can maintain a steady supply of equipment to our customers.

Logistics Risk

Another risk that we face is transportation disruptions, such as port or road closures, which can impact the delivery of equipment to our customers. We have enough backup suppliers that can be used in case of any closures to complete timely delivery. SOSC’s in-house logistic team is an expert in consolidating material from our stock and multiple sources. We are located close to Jebel Ali Port, which is the biggest seaport in the Middle East. Hence, from arranging suitable packaging and on-time deliveries in good condition to destinations far and wide to mitigating any transportation disruptions, our team of experts can handle it all. Our facility also has the closest access to Al Maktoum Airport and three major Highways allowing us access to multiple transportation routes in case of any closures.

Quality Risk

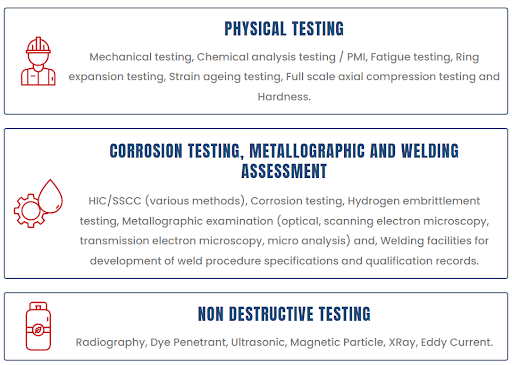

Quality issues with equipment can also pose a significant risk to our supply chain. We have therefore established worldwide relationships with main inspection houses like Lloyds, BVQI, SGS, IEI etc. A full inspection, verification, testing and certification service is undertaken before and after shipment when necessary and appropriate. Our QA/QC department can provide any (destructive or non-destructive) material testing, inspection and certification, whether to ASME, PED, Stoomwezen Rules, TÜV, IBR, Norsok or to your project specifications. We also maintain a robust supplier management system that ensures our suppliers meet the required quality standards.

Testing services offered by SOSC:

Cybersecurity risk

Cybersecurity risks are becoming increasingly important in the oil and gas industry, and we are not immune to this threat. We implement robust cybersecurity measures to safeguard our data and systems, including firewalls, encryption, and employee training to reduce the risk of human error. We also partner with reputable cybersecurity experts to identify and mitigate potential vulnerabilities in our systems.

Conclusion

As an oilfield supply centre, we are acutely aware of the significant risks that can impact our supply chain and, in turn, our customers. We take a proactive approach to risk mitigation, which includes maintaining a diversified supplier base, developing contingency plans for transportation disruptions, performing rigorous quality checks, and implementing robust cybersecurity measures. By adopting these mitigation strategies, we can minimise the impact of risks and ensure that our customers receive the equipment they need on time and without any issues. At the end of the day, we prioritise the satisfaction of our customers, and a robust risk mitigation strategy is a crucial component of achieving this goal.

Related News

Emerging Markets for Oilfield Supply Centres

Piping Accessories in the Oil and Gas Industry

API Standards and their Importance in the Oil & Gas Industry

How to Choose the Right Supply Centre for You?